Process

Turno Tech Auto Engineering Pvt. Ltd.

Bearing Manufacturing Process

Forging

Forging process stage of bearing manufacturing Turnotech Auto Engineering Private Limited uses high-quality steel SAE 52100 or 100CR6.

Sherardized Annealing

These forged bearing rings undergo a Sherardized annealing process which improves ductility and toughness with reduced hardness and strength.

CNC turning process

After completing the spheroids annealing process, the next process is the CNC turning process, Each ring undergoes dimensional and visual checking. One of the important steps for creating a highly durable, desired shape and long-lasting bearing.

Heat Treatment Process

Heat treatment involves the use of heating, normally to extreme temperature, to achieve the desired result such as hardening. This technique includes through hardening, tempering, norming, and quenching. which gives a stabilized ring structure and increases the lifespan of the bearing.

Grinding

Grinding is the most important process of manufacturing of bearing. This process takes place in three different phases namely surface grinding, face grinding, and OD grinding. To achieve accurate dimensions. Our machinery includes a face grinding machine (make Gardner) and centerless grinding machines (make Cincinnati) from WMW Germany. The grinding of the outer diameter of the cup under highly maintained tolerance. A complete line of imported, automized, CNC-controlled grinding machines with marposs in-process and post-process gauging.

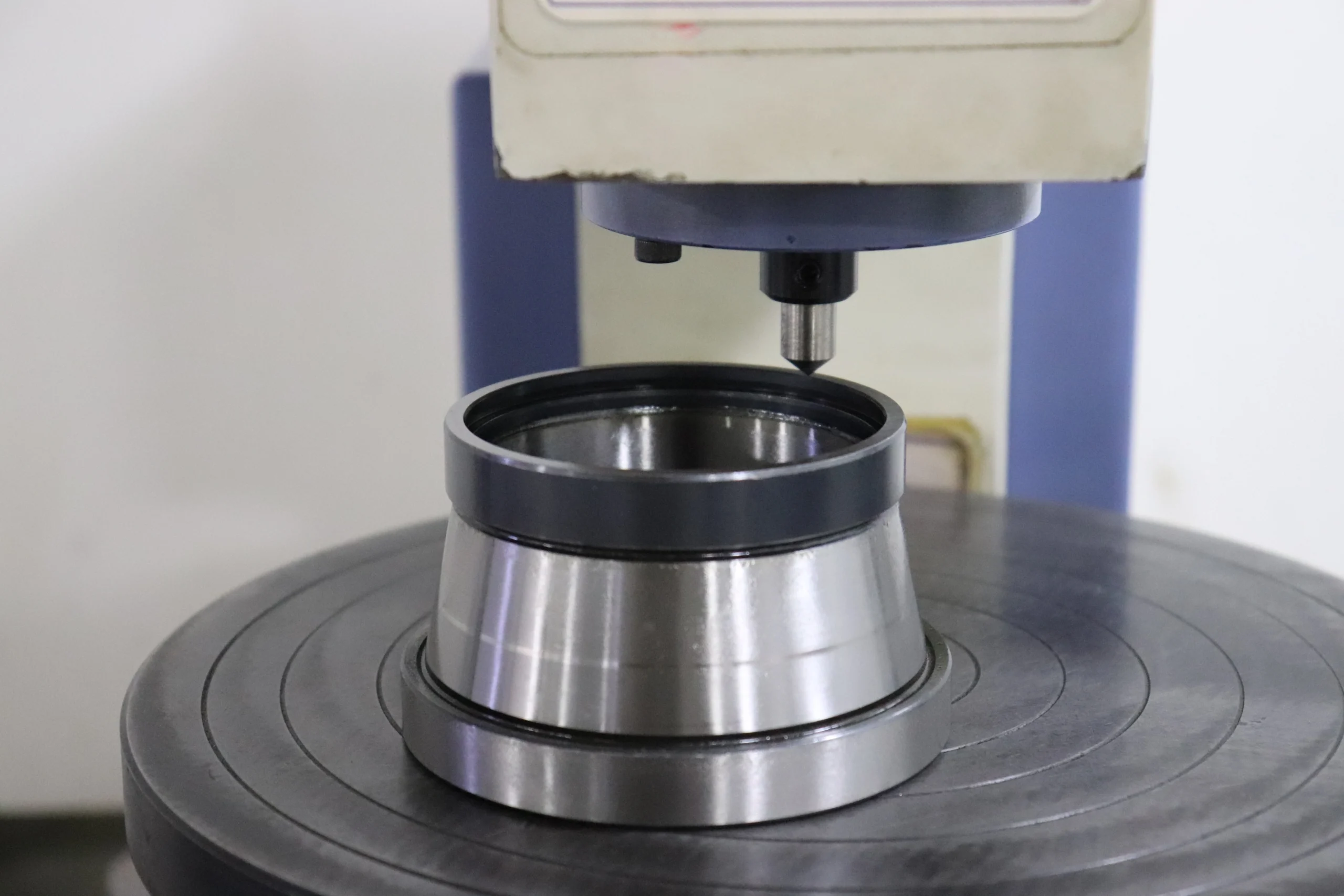

Inspection

Before assembling bearings, each ring is checked visually and the size of all the rings are checked by our engineers in our inspection room. We have a dedicated R&D plant to propel our vision for innovation. We have quality testing instruments like the Roughness Testing Machine, Roundness Testing Machine, Contour Measuring Machine, and Rockwell Hardness Testing Machine.

Assembly and packaging

Only after passing the quality test, components are taken for assembling.